Site Security Anchors: Best Practices for Preventing Equipment Theft

Wiki Article

A Comprehensive Summary of Anchoring Equipments for Your Following Job

A comprehensive understanding of anchoring systems is crucial for job success. Various kinds exist, including mechanical, glue, and growth supports, each suited for various applications. The choice of supports can substantially affect lots capability and product compatibility. Nevertheless, traversing this landscape needs careful factor to consider of several variables. What requirements should one focus on to guarantee efficient anchoring options? Discovering these nuances will expose the ideal practices for your details needs.Comprehending Various Types of Anchoring Equipments

When exploring different securing systems, it becomes obvious that each kind serves unique objectives and atmospheres. Supports can be classified right into several types, including mechanical, adhesive, and expansion supports. Mechanical anchors, such as wedge and sleeve supports, work by physically grasping the base material, making them perfect for hefty tons in concrete or masonry. Sticky supports utilize chemical bonding agents to safeguard themselves within drilled holes, providing extraordinary toughness in circumstances where standard mechanical supports might not be sufficient. Growth supports, which include toggle bolts, increase within the base material upon setup, distributing tons effectively. Additionally, specialty anchors, like those created for seismic applications, offer improved performance in dynamic problems. Understanding these diverse securing systems is vital for selecting the appropriate type that meets specific job needs and ecological factors to consider, making certain safety and structural stability. Each support type adds distinctly to the success of construction and engineering tasks.Applications for Concrete Anchors

Concrete supports are commonly utilized across numerous sectors as a result of their dependability and strength in securing frameworks. In building, they play a necessary duty in attaching components such as railings, shelves, and equipment to concrete wall surfaces and floors, making certain stability and safety and security. In addition, concrete anchors are essential in facilities projects, where they safeguard bridges, road obstacles, and signposts, adding to general architectural integrity.In the domain of production, these anchors are utilized to fasten equipment and heavy tools to concrete surfaces, minimizing vibrations and improving operational efficiency. They additionally locate applications in the installment of outside components like lights and fence, offering durability against environmental elements. Additionally, concrete anchors are used in the field of renovation, enabling reliable setup of new elements in existing structures. On the whole, their adaptability makes concrete supports a substantial component throughout several markets, boosting both safety and capability.

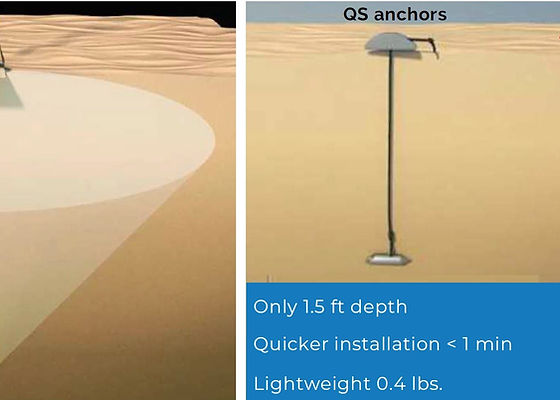

Discovering Screw-in Anchoring Options

Screw-in anchoring choices offer a sensible solution for safeguarding fixtures in different concrete applications. These anchors, commonly made as helical or spiral kinds, give enhanced holding power due to their threaded design that allows for efficient involvement with concrete. Their installment is simple; users can just pierce a pilot opening and after that screw the support into location utilizing a compatible tool. This removes the demand for extensive drilling or specific devices.Screw-in anchors are especially useful in scenarios where very Portable Building Anchors little disruption to the bordering product is preferred (Site Security Anchors). Their convenience makes them ideal for a series of applications, from protecting outdoor furniture to stabilizing architectural aspects. In addition, they can be gotten rid of and recycled, making them a cost-effective choice for short-term installments. Generally, screw-in anchoring alternatives present a trusted approach for attaining secure, reliable, and versatile securing options in concrete settings

Factors to Think About When Choosing an Anchoring System

Picking the appropriate securing system entails careful factor to consider of various elements that can greatly impact performance and reliability. Secret factors to consider include the type of substratum, as different materials call for details securing services for perfect grip. Tons needs are also crucial; the system must support the expected weight and anxiety without failing. Ecological conditions, such as exposure to dampness or chemicals, can influence the longevity of the anchoring system, requiring products immune to corrosion or destruction. In addition, installation ease and access may influence the choice, especially for jobs with restricted space or specialized tools. Finally, regulative conformity and safety and security criteria need to guide decisions to guarantee that the anchoring system satisfies essential lawful and efficiency benchmarks. By assessing these aspects, task managers can pick an anchoring system that provides stability and longevity, ultimately enhancing the general success of the job.Ideal Practices for Installment and Upkeep

When a tactical installment and upkeep approach is applied, the long life and performance of an anchoring system can be significantly improved. It is essential to comply with maker guidelines throughout installment, ensuring that all components are properly positioned and safeguarded according to requirements. Correct website preparation, including soil testing and environmental assessments, plays a substantial function in the system's performance.Normal maintenance checks ought to be arranged to examine for signs of wear, helping to loosen, or rust. Cleaning the anchoring components and surrounding locations from debris and contaminants is important to prevent premature failure. Furthermore, recording all maintenance activities supplies beneficial information for future analyses and modifications.

Making use of top quality materials and devices throughout both setup and upkeep reduces the danger of difficulties. Moreover, using skilled personnel guarantees that the anchoring system continues to be reliable, permitting for more secure and more reliable project results.

Frequently Asked Concerns

What Are the Most Common Materials Made Use Of in Anchoring Systems?

How Do Environmental Elements Influence Anchoring System Efficiency?

Ecological variables substantially affect anchoring system performance. Variables such as soil kind, wetness levels, temperature fluctuations, and seismic activity can impact security, load-bearing ability, and general performance, necessitating careful assessment throughout task preparation and application.Can I Reuse Anchors After Elimination?

The inquiry of recycling anchors after removal relies on the type and condition of the supports. Site Security Anchors. Generally, if they reveal no indicators of damages or rust, they might be safely reused for comparable applications

What Is the Life-span of Normal Anchoring Systems?

The life expectancy of common anchoring systems differs based upon products and environmental problems. Usually, metal supports last 10-20 years, while plastic or composite options might last 5-10 years, depending upon direct exposure and usage variables.Exist Any Type Of Rules Concerning Anchoring System Installment?

Rules regarding securing system setup vary by region and application - Portable Building Anchors. Commonly, they encompass safety and security criteria, environmental factors to consider, and product specs, guaranteeing the systems fulfill necessary performance and durability demands for their meant useSupports can be categorized right into a number of types, including mechanical, sticky, and development supports. Mechanical supports, such as wedge and sleeve anchors, work by literally gripping the base material, making them suitable for hefty lots in concrete or masonry. Sticky anchors use chemical bonding agents to secure themselves within pierced openings, giving phenomenal toughness in circumstances where standard mechanical supports may not suffice. The most usual materials utilized in securing systems include steel, concrete, and polypropylene. The inquiry of recycling anchors after elimination depends on the kind and condition of the supports.

Report this wiki page